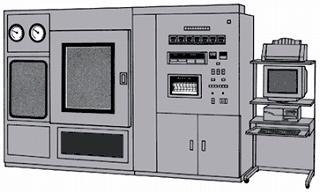

Full Automatic Compressor Performance Testing Equipment

Full Automatic Compressor Performance Testing Equipment measures refrigeration capacity of a compressor of an air conditioner for automobiles.

- All measuring items form compressor control and measurement to capacity calculation and data listing are processed automatically.

- Measurement time is shortened by improvement of control stability and calculation process.

- Highly accurate capacity measurement is enabled by precise measurement and calculation system

- Excellent repeatability and capacity comparison of prototypes is done effortlessly.

- It is capable of OCR measurement in real time.

System Configuration

| Calorie Meter System | Compressor driving equipment Refrigeration cycle Compressor temperature chamber |

|---|---|

| Measuring and Controlling Component | Controller Data Logger Communication Interface PC |

| Additional Component | Chiller unit Cooling water bath |

| Measurement System | Total refrigeration capacity of compressor, net refrigeration capacity, shaft horse power, coefficient of performance (COP), volume efficiently, and mechanical efficiency etc. |

| Control System | Control of parameters such as compressor revolution, compressor ambient temperature, discharge pressure, front temperature of expansive valve, etc. and operation |

| Data Processing System | Calculation of total refrigeration capacity of compressor, net refrigeration capacity, shaft horse power, and coefficient of performance, etc. |

System Specification

| Testing Method | By direct method stated in JIS B8608 “General rule of capacity measuring method of refrigerating unit” |

|---|---|

| Measuring Range | Refrigeration capacity 1000 to 12000W (standard) |

| Capacity Measuring Item | Total refrigeration capacity-JIS refrigerant flow meter method Net refrigeration capacity –JIS electric heating method based on JIS calorie meter method shaft horse power, coefficient of performance (COP), volume efficiently, and mechanical efficiency etc. |