IoT monitoring system in manufacturing plants

Chino uses its measurement and control technology to propose monitoring systems that meet customer needs.

- Monitor all process in real time using touch panel or smartphone!

- Past data can be easily replay in the office or on-site using the condition function!

- Realize a monitoring system suitable for early detection, prediction, and improvement of manufacturing defects!

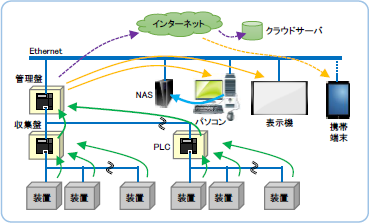

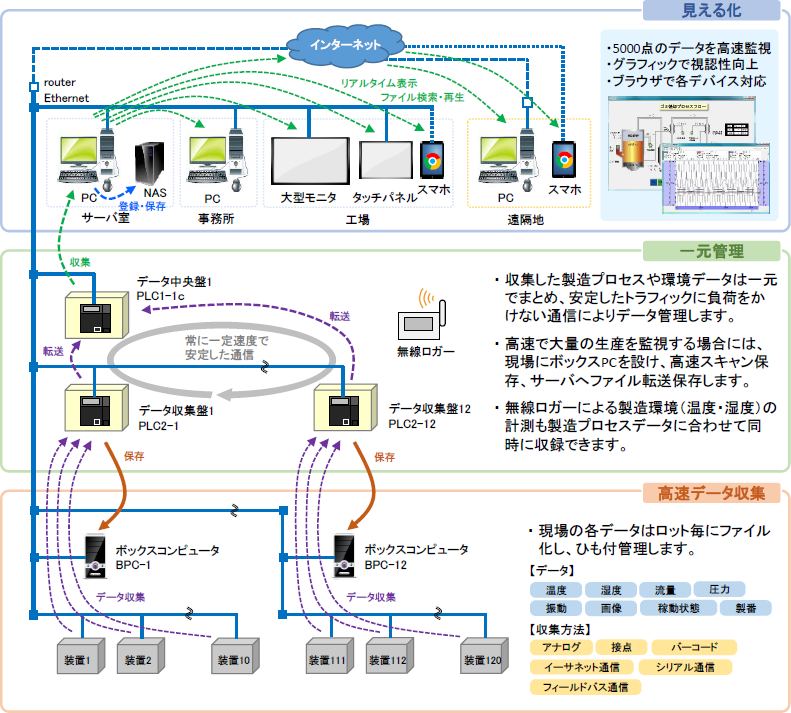

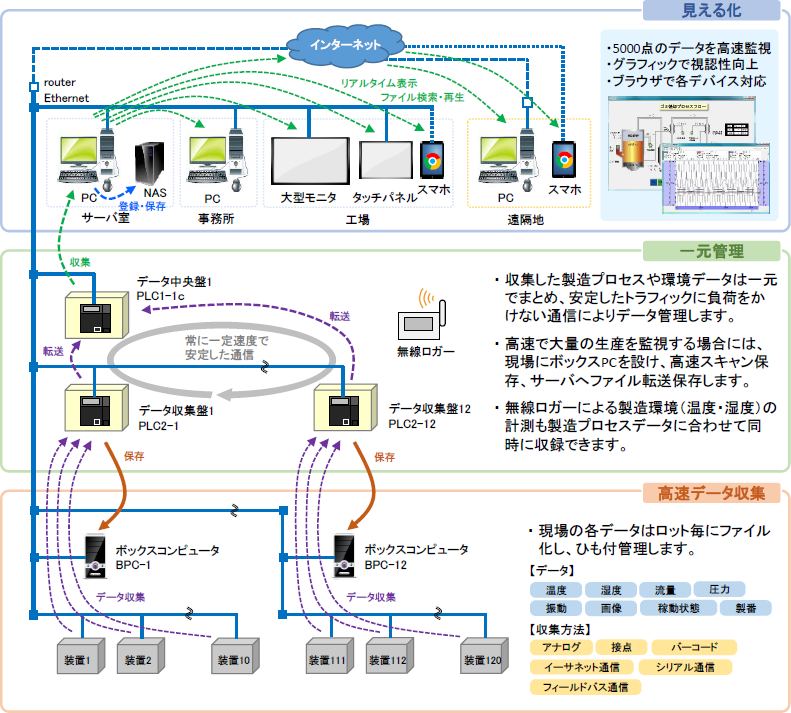

IoT Visibility anytime, anywhere

IoT

- Manufacturing data is collected high-speed and reliably.

data logging is highly versatile and can easily accommodate device relocation or expansion.

- All kinds of data can be collected.

It is also possible to collect manufacturing process data such as temperature and pressure, equipment operating status and site environment data, and process management data such as production lot number and serial number.

Network Monitoring

- Collected data can be display in real time and monitored from the office, in the field, or remotely.

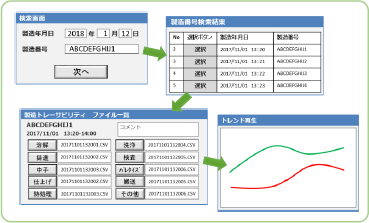

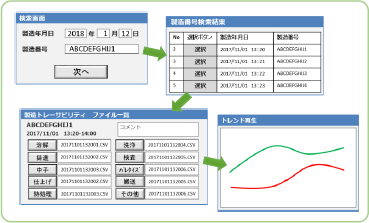

Traceability management of manufacturing data

Attached management of quality data

- The collected data is constantly saved (duplicated possible).

The stored data is regularly compiled into a database and linked to product manufacturing data, making it easy to search.

- Saved files are display in a list, making it easy to search for data by lot number, serial number, production date and time, etc.

Promoting the use of big data

- By having on-site personnel check the results of the previous process, it helps improve production and reduce defects.

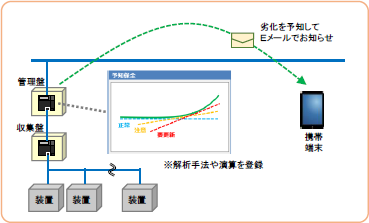

Predictive maintenance: Predict the deterioration of production equipment

Preventive maintenance is possible by predicting equipment deterioration

- Being able to predict when equipment needs to be updated reduces the risk of production downtime.

- By calculating the equipment's operating time, vibration data logging, and various computation such as the Mahalanobis-Taguchi (MT) method, maintenance time is notified.

- display light and email will notify you when maintenance is required.

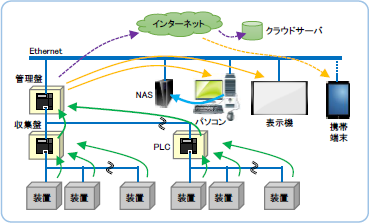

IoT monitoring system configuration

Monitoring Package Software

The monitoring package software CISAS/V4 is a build-type real-time monitoring application. Since it is a general-purpose packaged software rather than a one-off build, it keeps implementation costs down and allows for a smooth system startup.

Although it is a standard product, it is also highly expandable, and required functions can be incorporated as external applications.

Key Features

- Real-time trends

- Data List

- Graphic Monitor

- Alarm Summary

- memory operation

- Report

- Email notification

Useful option

- high-speed acquisition function CISAS-CX

On-site data is collected at high-speed of up to 20 msec.

- Remote monitoring function CISAS-Web

The CISAS screen can be monitored via the Internet.